Paint

Design paint

Painting on the plastic makes the product improve the

appearance and protect the material.

So far, we have supplied design paints to a wide

range of industries such as automobile interior and exterior, mobile phones,

light electric appliances, and medical devices for cosmetics.

With the cooperation of paint manufacturers, we are working to create new design

that have never existed before.

Functional paint

This is to introduce of functional paints that are increasing to gain attention.

Antibacterial paints are attracting attention due to the influence of the COVID-19,

Non-slip paints used for anti-slip purposes,

Lubricating paints used for the opposite purpose of non-slip paints.

To improve scratch resistance, UV paint with high hardness is generally used,

However, self-healing paint that restores shallow scratches over time is also recommended.

In the case equipment installed outdoors inevitably retains heat.

There is also a paint that dissipates heat from the inside and shields heat from

the outside.

Solvent/Processing agent

As solvents, there are two type of thinner.One is for dilution which is used by mixing with paint,the other for cleaning for jigs and painting equipment.

Especially sludge is very stickyin UV-painted booths so that a flocculant is indispensable.

In addition, a purge material is available as cleaning when changing the color of the molding machine.Please feel free to contact us.

Secondary material

As masking tape for using of curing before painting, we have handled various types of masking tape such as heat-resistant type and the type which left few traces to peel it off.

In addition, as surface treatment, we have handled abrasives and papers for fabrics, polishers for removing lumps after painting,etc.

To blend the paint,we handle electronic scales and, filtration paper, pot containers ,etc.

To make sure about the condition after painting,a film thickness meter and color difference meters are available.

Facility / Jig

Facility

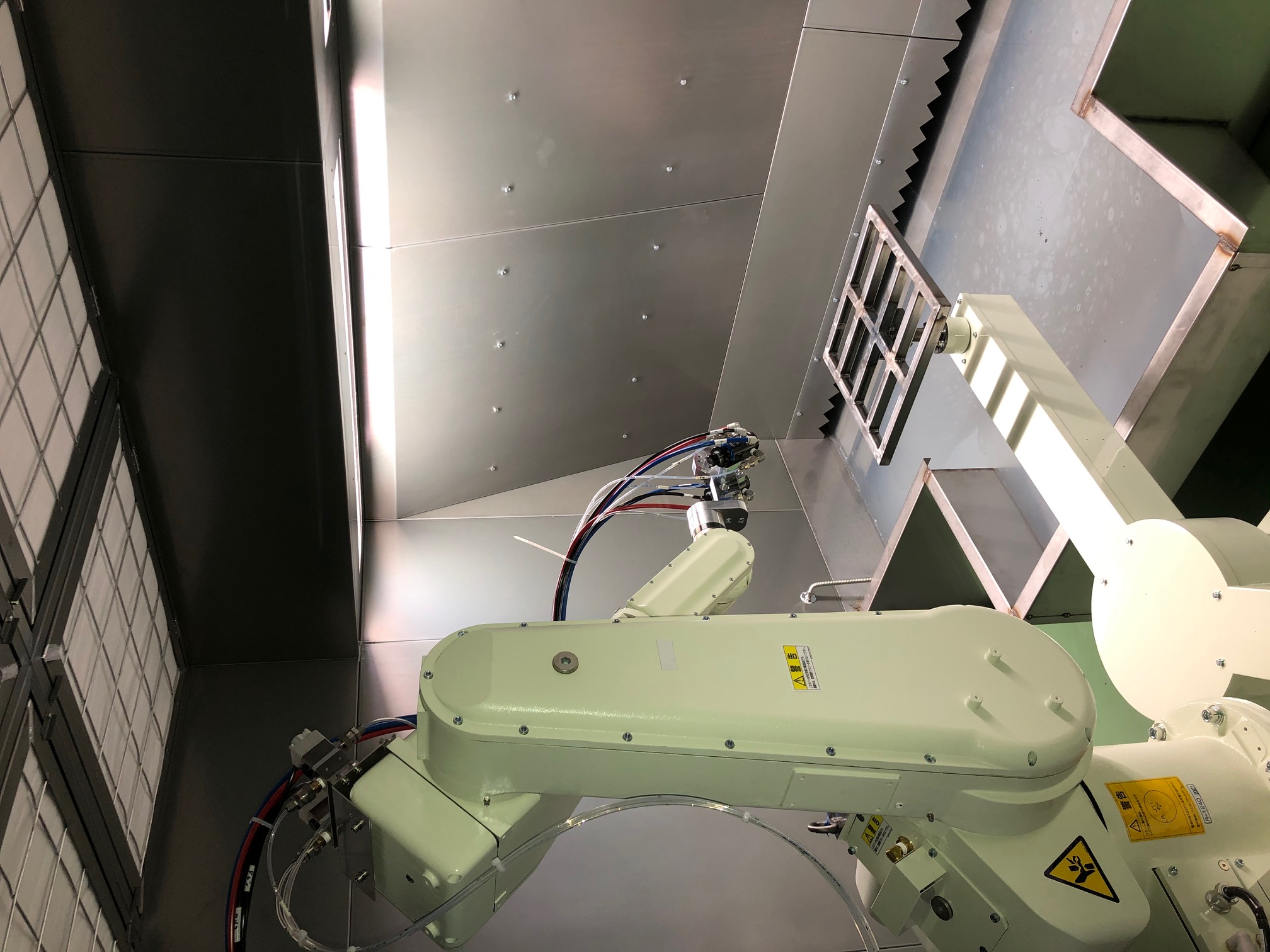

We handle total general equipment related to painting.

The large scale in the general equipment is painting plants.

To be simply put, it refers to the whole equipment of the painting process from the beginning to the end.These are included with lines, which make the product paint and transport and dry, and with painting booths, exhaust ducts that discharge paint mist generated at booths to the outside.

The medium scale is the robot.

There are painting robots, and also transfer robots that carry workpieces.

Along with these, you will need an automatic gun or

paint pump.

The small scale are the hand spray guns used for hand-blown painting and so on.

Jig

We have handled to manufacture electroformed masking jigs for painting, electroformed masking jigs for vapor deposition, sheet metal jigs, resin jigs, etc. also different printing jigs and inspection jigs.

So please do not hesitate to tell us your request.

We offer to support you from the product development to mass production.

We also have great backup service after delivering the product.